Hotline

Search:

On April 27, 2024, the 16th Chongqing International Battery Technology Exhibition (CIBF2024), a global carrier level event in the battery industry, was held as scheduled at the Chongqing International Expo Center.

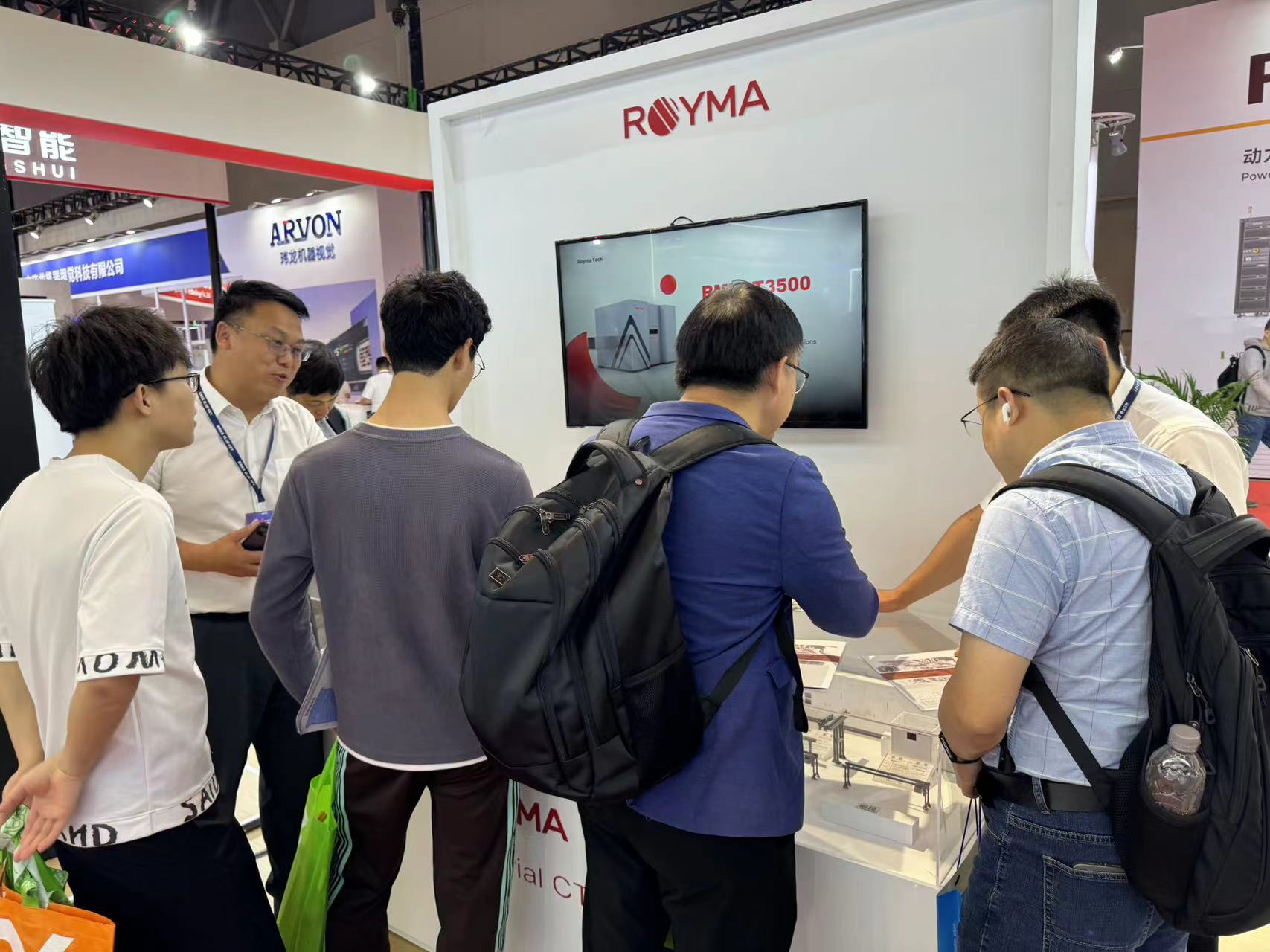

During the exhibition, Royma showcased its full range of battery quality solutions and numerous intelligent inspection equipment at booth T009 in Hall S1. Let's review the grand occasion of the exhibition together!

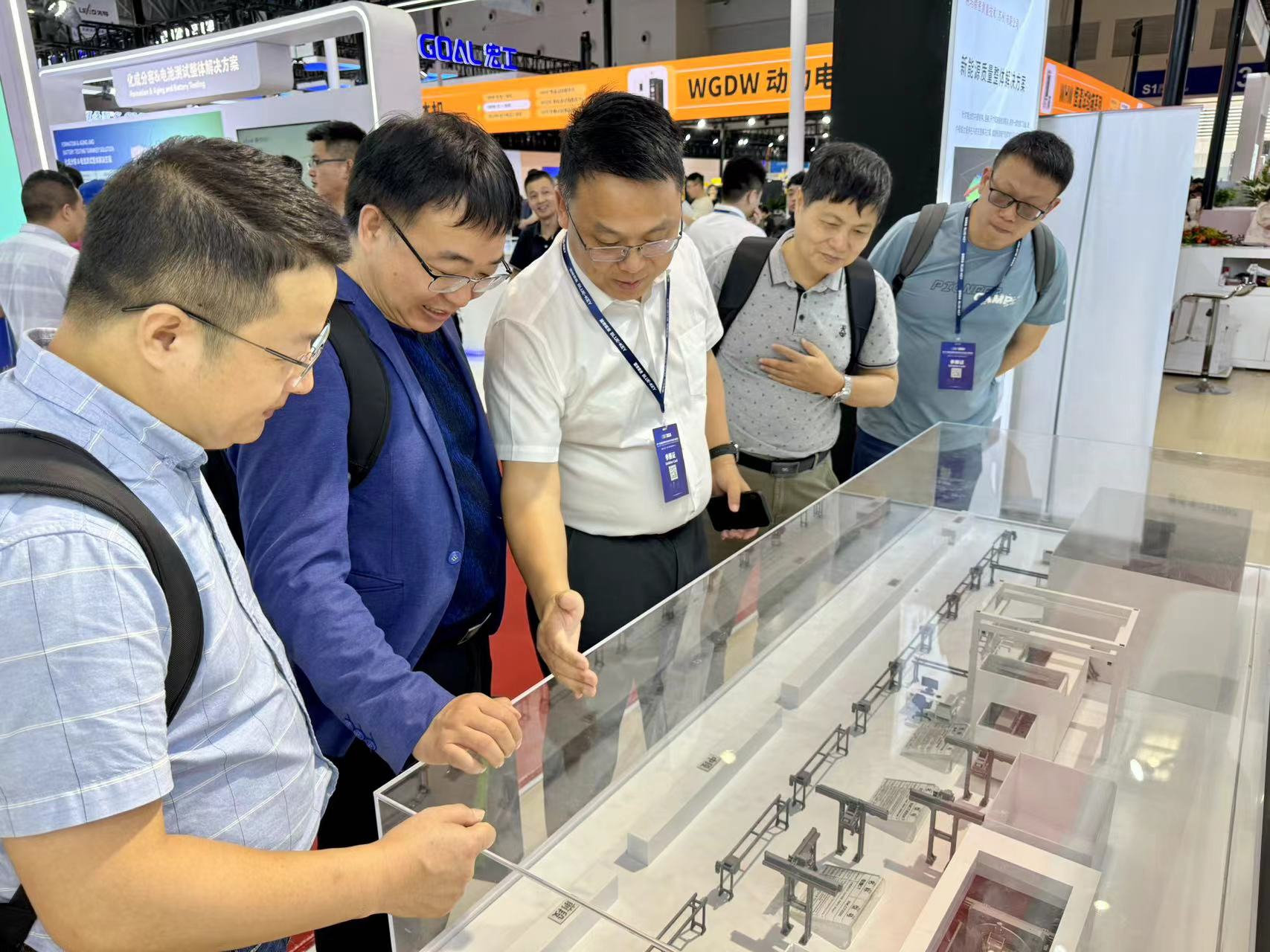

The CIBF2024 exhibition site was crowded with people, and the Royma booth was particularly lively. Industrial CT technology continued to attract attention. Leading companies in the new energy industry, such as BYD, visited the Royma booth one after another to exchange CT quality management technology with on-site experts.

In recent years, the key terminal areas relying on battery technology have been continuously growing. Any errors or malfunctions in batteries have a stronger impact on consumer safety and product confidence than ever before.

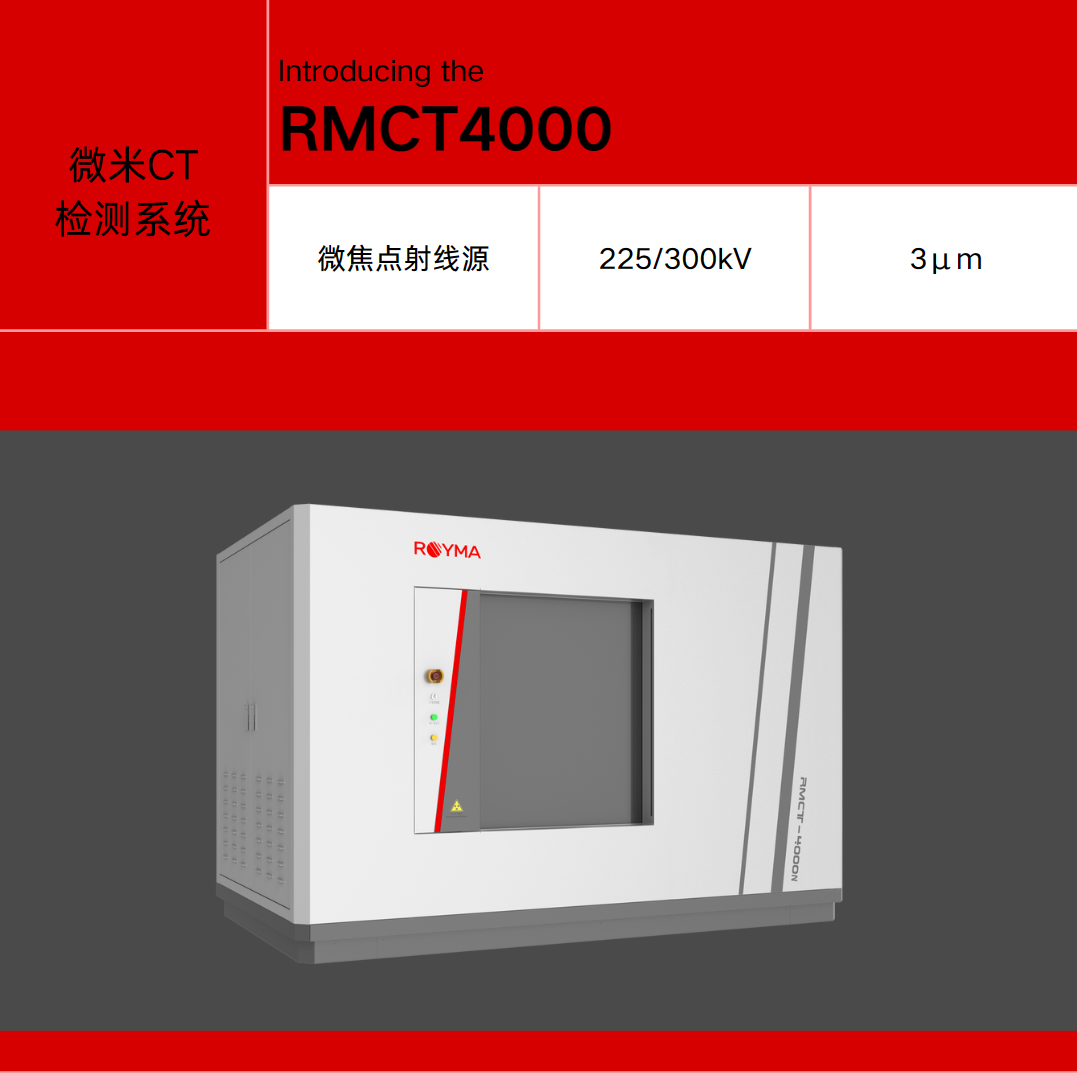

We provide high-resolution 3D CT scanning and 2D X-ray imaging services to assist battery manufacturers in achieving efficient and perfect quality control throughout the product lifecycle.

Among them, inline CT, as a future technology, has attracted much attention and is the most popular product on site. During the scanning process of inline CT, the battery cell remains stationary and the probe rotates, making it friendly to the sample without clamping force; At the same time, the device is equipped with an AI algorithm function module independently developed by Royma, which can achieve fast and accurate OH automatic point capture calculation, and meet the high-precision and high-efficiency customer needs, as well as GRR (measurement repeatability and reproducibility) measurement data requirements, and can adapt to fast and efficient industrial assembly line inspection.

Battery materials

Using nanoscale high-resolution CT to study the microstructure characteristics of battery positive and negative electrode materials. Using the powder analysis module in VG software, you can describe the size and shape of each individual particle of the active material and quantify it in global statistics. In addition, particle size distribution can be studied in a certain direction to observe the variation of particle size or shape with coating thickness.

Battery cell

By using industrial CT scanning, engineers can have a comprehensive understanding of the internal electrode structure. Accurate 3D imaging and visualization of complex details of electrode configuration reveal the range and distribution of anode protrusions, winding conditions, as well as defects such as wrinkles and protrusions, enabling battery engineers to improve product design and manufacturing, opening up new possibilities for energy storage solutions in many industries.

parts

Royma CT can provide dimensional accuracy, sealing, and welding quality control for battery cover plates.

module

The application of CT can quickly and accurately detect the quality of adhesive coating (uniformity, thickness, and coverage), and automate this process to improve production efficiency and quality control level.

The grand event came to an end with great honor. Gratitude for meeting, never stopping. The influx of guests has allowed Royma to shine at the exhibition, and we will continue to monitor market trends, optimize product performance and service experience, and help customers achieve dual improvements in production efficiency and quality. Looking forward to meeting again next time!

Get in touch with us, our experts will help you