Hotline

Search:

From July 3 to 5, the Shanghai New International Expo Centre hosted the world’s largest automotive engineering trade show—AMTS (Shanghai International Automotive Manufacturing Technology & Equipment and Materials Exhibition). This grand gathering of global top-tier automotive technologies provided an excellent platform for Royma to showcase its latest achievements in industrial CT. As one of the few domestic suppliers with independent R&D capabilities, Royma presented its advanced industrial CT and inspection technology solutions, engaging with other industry peers to discuss the future of automotive manufacturing.

A Strong Product Display for the First Time

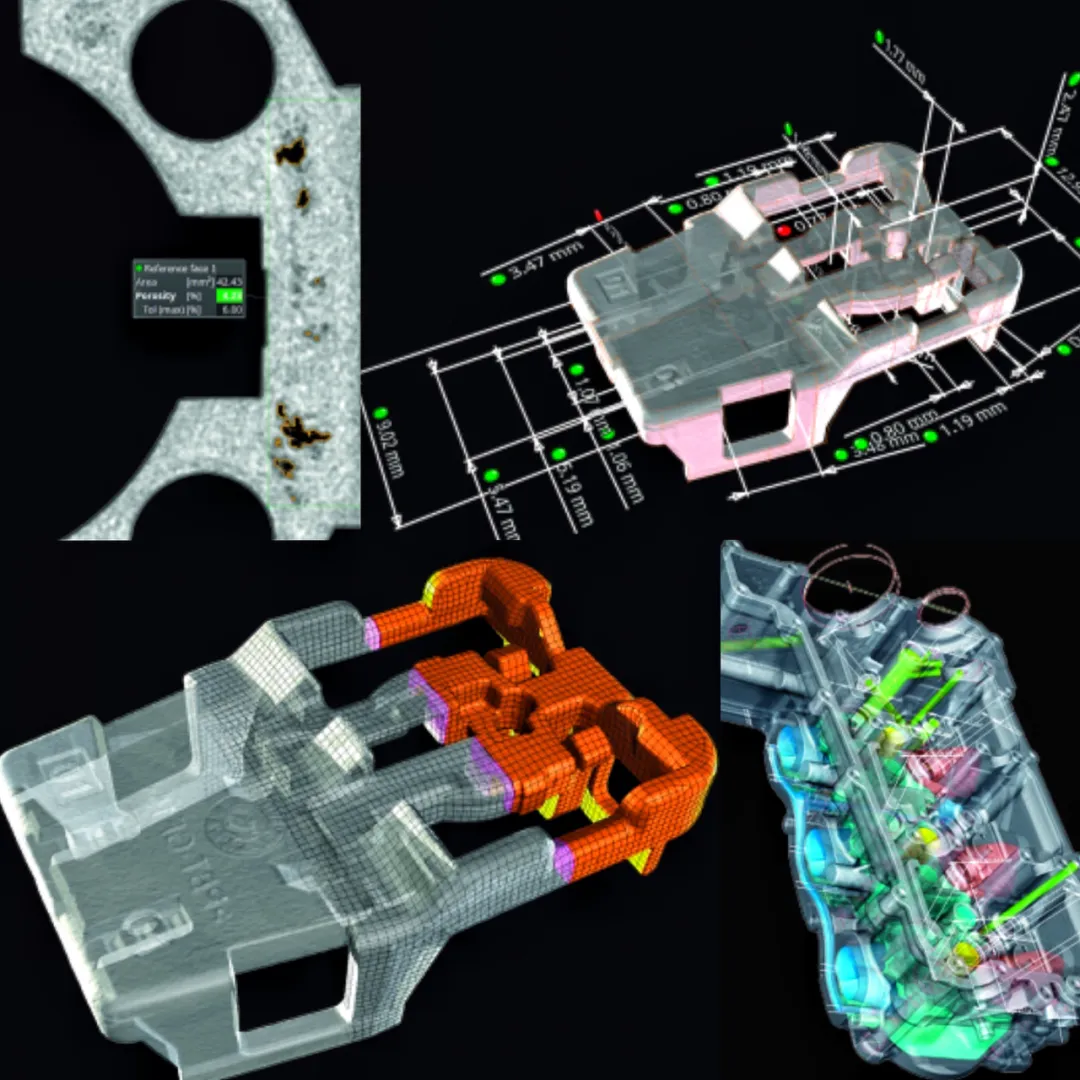

At the exhibition, Royma showcased its high-resolution 3D CT scanning “flagship model,” the micron CT monitoring system, as well as its industry-leading online CT inspection machine. Both systems feature high-resolution 3D CT scanning and 2D X-ray imaging technologies, demonstrating exceptional capabilities in the automotive manufacturing sector.

As globalization and market competition intensify, the demand for intelligence, efficiency, and sustainability in automotive manufacturing is growing rapidly. Industrial CT inspection technology, a non-destructive testing method, offers significant advantages such as high precision, high resolution, and high efficiency. It provides high-definition, non-destructive imaging of internal structures, revealing defects, cracks, and foreign materials. Whether it’s the quality inspection of key components like engines, chassis, and body, or the internal structural analysis of automotive electronics, motors, and new energy lithium batteries, high-precision scanning imaging technology enables non-destructive detection of complex internal structures. This allows for precise detection of material defects and welding quality, ensuring product quality and safety, identifying potential issues in time, and providing strong support for product development and manufacturing, safeguarding the quality and safety of automotive products.

Applications of Industrial CT in Automotive Manufacturing

As a leading domestic and globally recognized industrial CT inspection brand, Royma has established long-term cooperation with leading automakers and component manufacturers, such as BMW, BYD, Geely, Tesla, and Bosch. It provides comprehensive industrial CT scanning, non-destructive testing, microscopic analysis, material analysis, reliability analysis, and failure analysis services. Royma not only provides high-quality technical support for the automotive manufacturing industry but also works hard to establish a good reputation and influence for domestic industrial CT inspection brands.

Looking Ahead,Royma is committed to the corporate vision of “creating a world-renowned smart technology brand” and continues to enhance its technical strength and market competitiveness. Through continuous technological innovation and product upgrades, Royma aims to provide more efficient, precise, and reliable industrial CT inspection services for the global automotive manufacturing industry, driving the sector toward smarter, more efficient, and sustainable development.

For more product and solution details, please call us

400 797 8899

Get in touch with us, our experts will help you