Hotline

Search:

The development level of the aerospace industry is of great significance to a country, as it involves multiple aspects such as national security, economic development, technological innovation, education and training, and international influence. Therefore, countries around the world attach great importance to the development of the aerospace industry and invest a large amount of resources and energy to promote progress in this field.

Since the 1950s, China's aerospace industry has made significant progress in over half a century, becoming one of the world's most important aerospace powers.

Correspondingly, detection technology also needs to keep up with the times. Many new requirements that are difficult to meet in traditional detection technologies, such as high precision, high efficiency, multifunctionality, automation, non-destructive and traceability, call for the upgrading and replacement of detection methods in the aerospace industry.

In this context, on October 28th, the "China Aviation Industry Advanced Inspection and Measurement Capability Development Forum and Special Committee Establishment and Supply Demand Matchmaking Conference" hosted by AVIC International Supply Chain Technology Co., Ltd. was held in Ningbo.

Mr. Sun Xiaotao, Vice President of Lima Precision Testing, was invited to attend the conference as an outstanding supplier representative, demonstrating the application capabilities and quality solutions of industrial CT in the aerospace field to over a hundred professional audiences.

At the speech venue, there were no empty seats, and many viewers took out their phones to take photos and record the exciting content of the speech. Some viewers even went to the exhibition hall of Lima Precision Testing with great interest to visit and exchange ideas.

俐玛精测副总裁孙晓涛先生,正在演讲

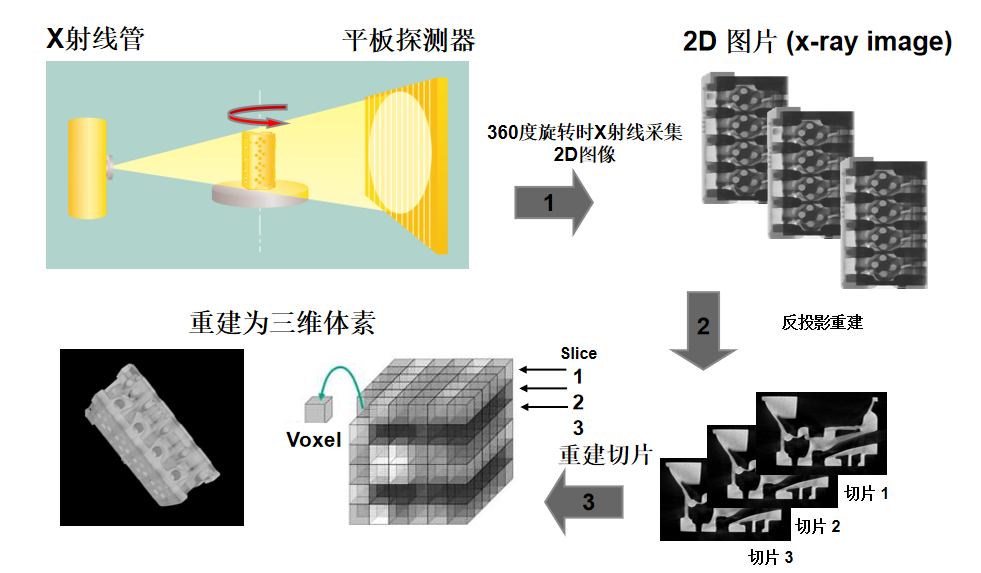

In the 1960s, CT technology was first applied in the medical field for non-invasive examination of the human body, and then gradually applied in the industrial field. It can be said that it is still a very young technology. However, its application in the aerospace field began as early as the 1980s, mainly for defect detection of engine internal structures.

工业CT技术的运作原理

After the speech, we had a more in-depth discussion with Mr. Sun. Below is a summary of our conversation.

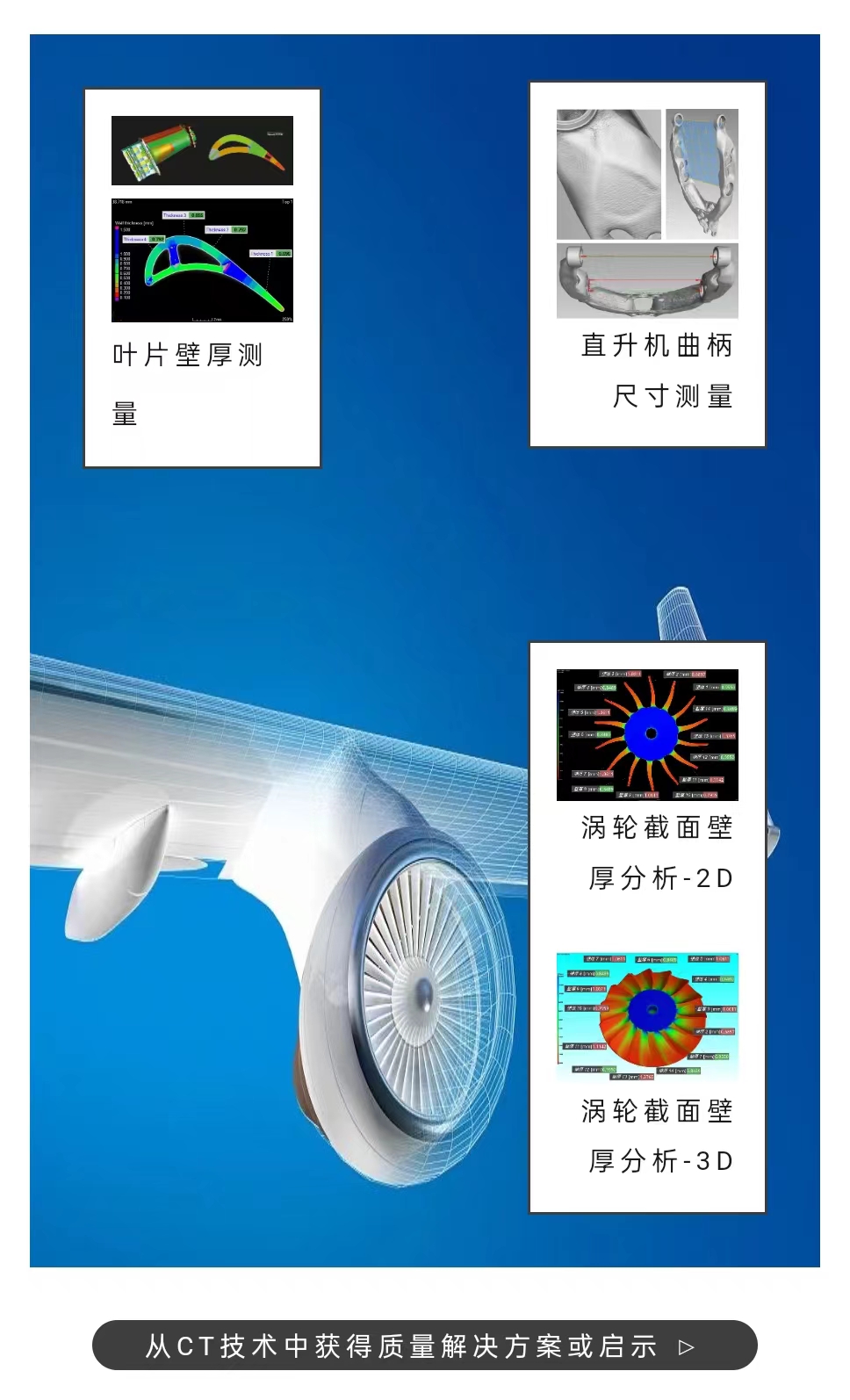

Q1: The CT inspection cases and images of blades, turbines, fairings, pyrotechnics, and various additive manufacturing components you presented in your speech were extremely captivating and impressive.

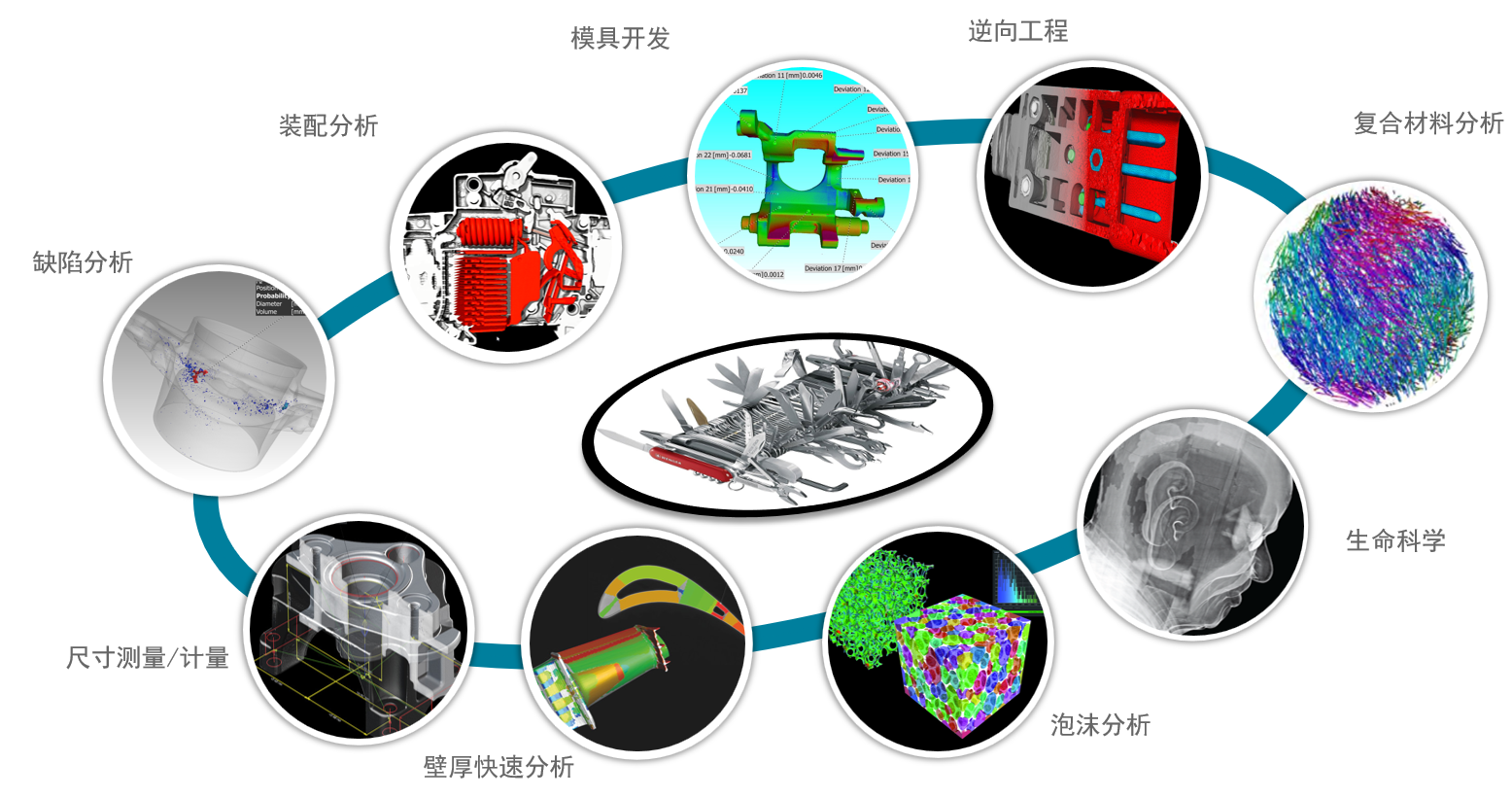

Thank you for your affirmation. In addition to what was showcased in the speech, industrial CT, in fact, has excellent coverage in aviation inspection. Key issues that drive transformation in the aerospace industry, such as materials, structures, propulsion systems, electronic systems, data analysis, and prediction, can all find solutions or inspirations from CT technology to tackle uncertain quality pitfalls or challenges.

Q2: Testing in the aviation industry may face more challenging issues than other testing samples, with stricter standards for accuracy and reliability. Do Lima's existing products or technologies have sufficient preparation or confidence in this?

We are well aware that the aerospace industry has a very low tolerance for faults and defects and an extreme pursuit of accuracy. Therefore, the solutions or products we provide to aerospace industry clients are based on countless desk research, field visits, and testing experiments to obtain the "optimal solution". This' solution 'will continue to be optimized and broken through with the development and updates of technology.

At present, we have developed various unique scanning technologies for workpiece detection in the aviation industry, such as limited angle scanning, extended stitching scanning, virtual axis scanning, and free trajectory scanning (FCT), to meet the image capture needs of large samples. In addition, we also have scanning modes designed for different detection environments and rhythm requirements, such as fine scanning, fast scanning, and non equal step scanning.

Lima's independently developed hard core technologies such as reconstruction algorithms, intelligent detection and AI image enhancement algorithms, excellent artifact removal techniques, system semi/automatic verification and correction techniques have also been proven effective and of great value in practice. Overall, we have great confidence in successfully completing testing or analysis tasks in the aviation field.

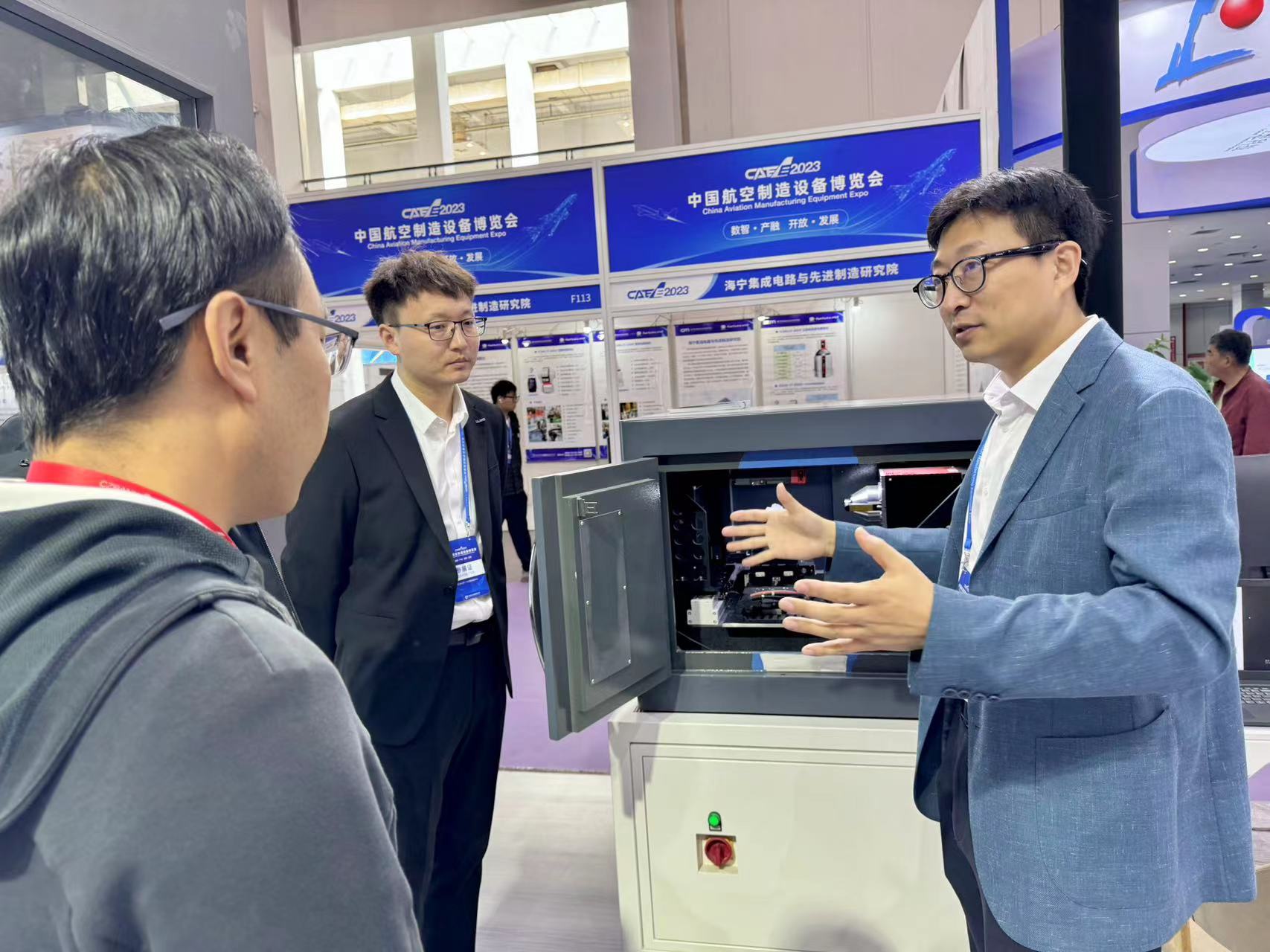

CAEE2023中国航空制造设备博览会上,俐玛精测工作人员正在为观众做讲解

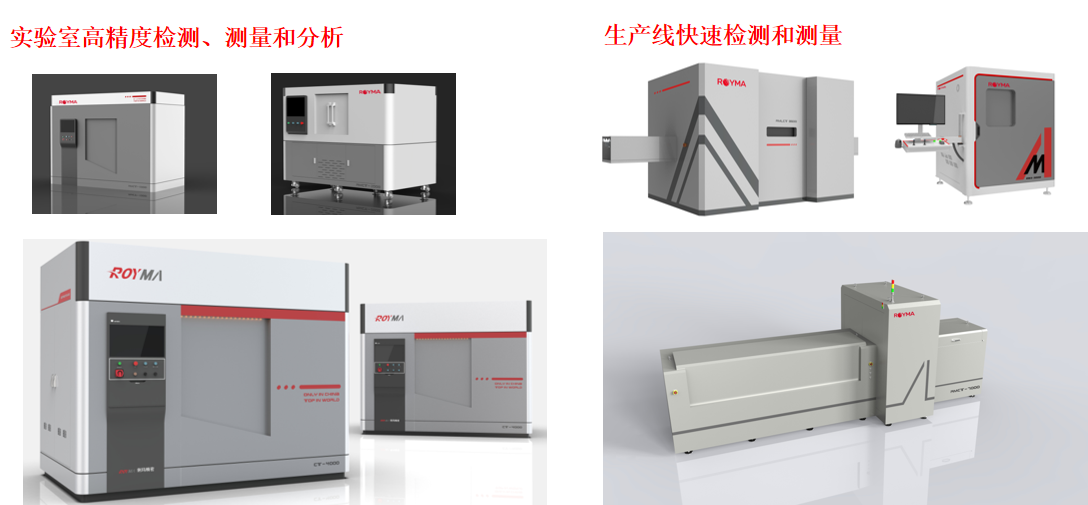

Q3: What products can Lima recommend for aviation industry testing now?

Lima's current X-ray and CT product lines can meet the detection, measurement, and analysis needs of both laboratory and production line scenarios. According to the size, density, thickness, and testing requirements of the inspected workpiece, we have desktop CT, horizontal CT, online CT, nano CT, micro focus CT, high-energy small focus CT, and high-energy large focus accelerator products to choose from.

The changes in the workpiece are like "thousands of people, thousands of faces", so the detection plan is not unique and fixed. We provide customized testing solutions with high adaptability to meet specific customer needs. We can provide flexible and diverse choices in product design, scanning technology research and development, and collaboration methods - all with the sole purpose of helping leaders in the aviation industry fully tap and utilize the potential of CT technology to create remarkable success.

Lima Precision Testing Product Series (Part)

At CAEE2023 China Aviation Manufacturing Equipment Expo, Mr. Sun Xiaotao is introducing Lima's desktop CT to the audience

Q4: Apart from aerospace inspection, what other application areas are there for industrial CT?

The application fields of CT are very extensive, including automobiles, new energy batteries, semiconductors, electronic manufacturing, medical equipment manufacturing, and mechanical manufacturing (such as gears, shafts, connecting rods, and other mechanical components), all of which have industrial CT application scenarios and opportunities. It is compatible with multiple detection technologies and measurement analysis needs, making it a highly cost-effective and investment return option. Under certain complex workpieces and strict inspection requirements, industrial CT is even the only choice.

Lima Industrial CT: Leading the Sustainable Aerospace Future

In the face of the complex internal structure and inability to disassemble aerospace inspection components, industrial CT displays product performance and structural features intuitively through three-dimensional visualization inspection methods, which meets the quality inspection needs of high-precision and high sealing aerospace components. It can also help manufacturers improve efficiency in product surface defect and failure analysis, rapid product design and verification, workshop production, and quality laboratory testing. From this perspective, industrial CT technology has important application prospects in aerospace inspection and may become a key technology for the transformation of aerospace inspection.

If you have any needs for sample testing, equipment rental, or purchase, please feel free to contact us at 400-7978899. Lima Precision Testing is dedicated to serving you.

Get in touch with us, our experts will help you