Hotline

Search:

Lithium batteries are one of the commonly used energy storage devices in electronic devices, fixed power sources, and electric vehicles.

Manufacturers and suppliers must ensure compliance with quality and safety standards while striving to increase production capacity, reduce charging time, and extend the lifecycle.

Lithium batteries in consumer electronics have reached the mature mass production stage, but the maturity of new batteries and battery packs suitable for electric vehicles is still several years behind.

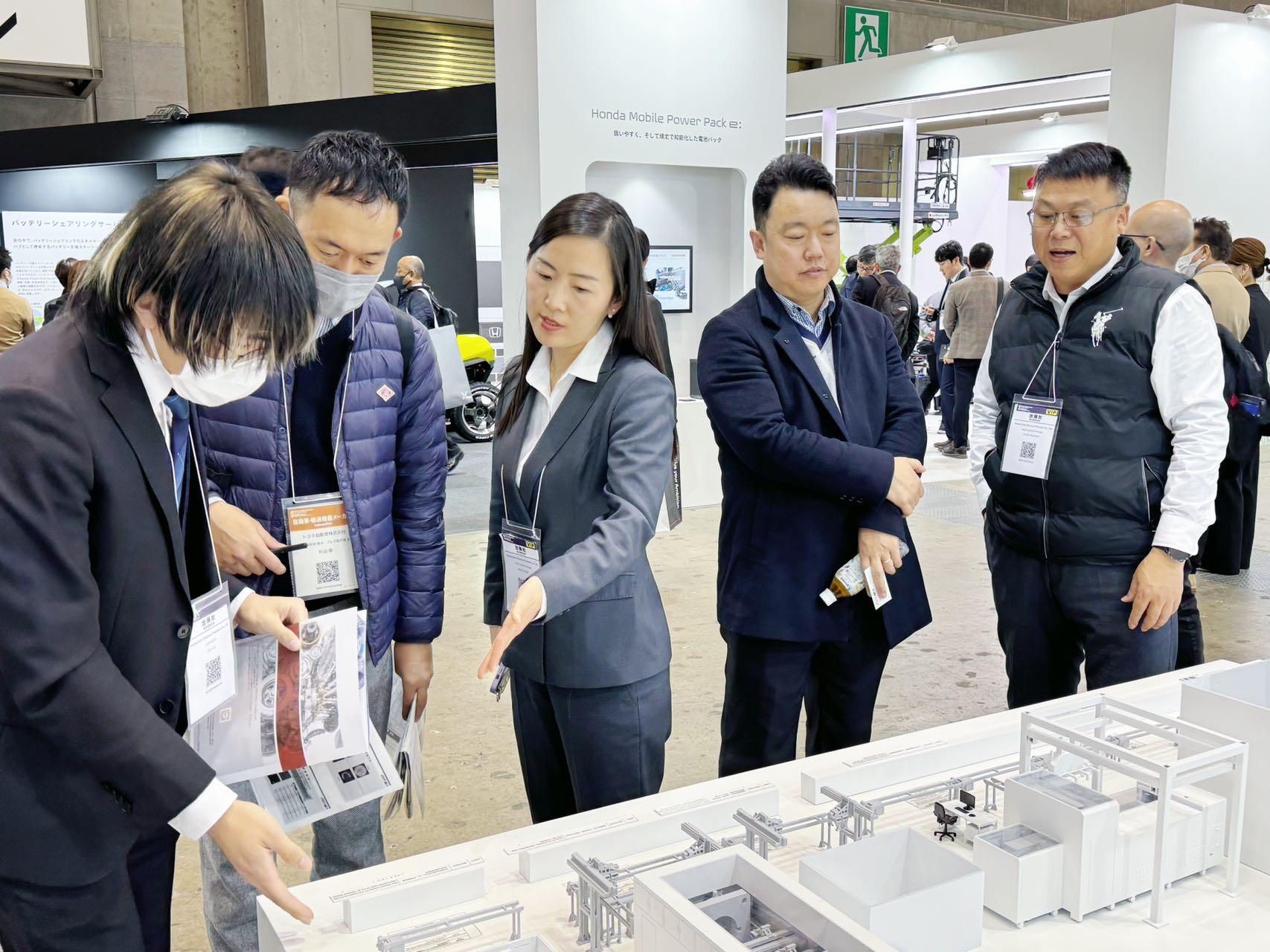

On February 28th, Japan International Smart Energy Week and SMART Energy WEEK were held at the Tokyo International Exhibition Center.

Lima Precision Measurement Technology (Suzhou) Co., Ltd., an industrial quality control technology company from China, showcased its innovative industrial CT detection products and solutions at booth E38-43.

In China, Lima Precision Testing has established cooperative relationships with leading enterprises in the fields of new energy, die-casting, and automotive manufacturing. Lima Precision Testing's industrial CT products have been inspected and recognized in key tasks in laboratories and production workshops. In 2024, Lima Precision Testing hopes to expand its market in Asia Pacific regions such as Japan and South Korea.

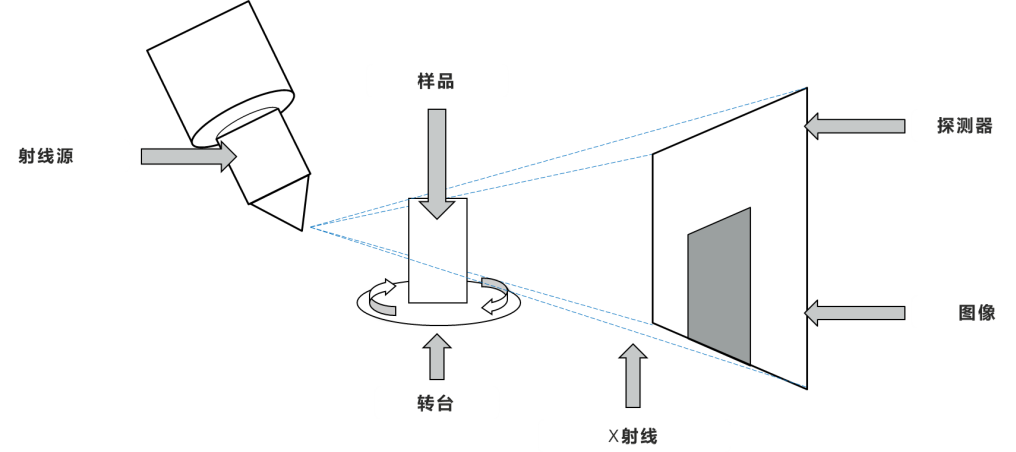

工业CT是一种利用X射线穿透材料并通过计算机处理从而获得被测物体内部结构的三维图像的技术。与传统的二维X射线检测相比,工业CT能够提供更加详细和全面的内部结构信息,包括缺陷的大小、形状、位置以及分布情况,从而为产品质量控制提供了更为准确和直观的依据。

From research and development to production, fault analysis of defective batteries, scanning analysis of scrapped batteries, industrial CT testing supports quality control and fault analysis at various stages of the battery life cycle.

Lima Precision has established a complete CT product line, including vertical CT, horizontal CT, and planar CT. Among them, multiple micro focus CT, micro nano CT, and online CT can provide safe and reliable line edge/online production control, and perform reliable testing on all important components.

211/10000

Real time translation

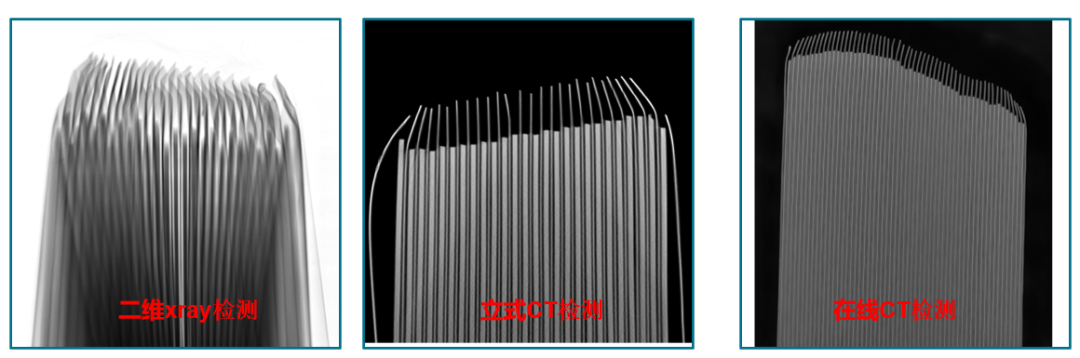

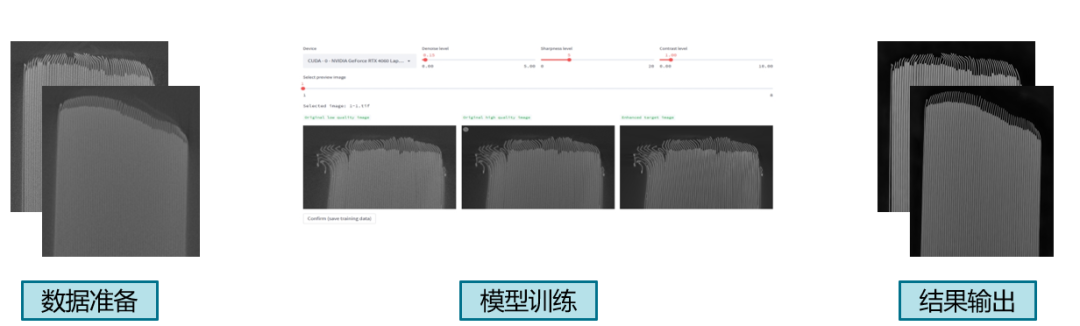

Automation and intelligence are the trends in the development of industrial CT testing. High performance X-ray sources and detectors, efficient reconstruction algorithms, and intelligent data analysis algorithms are the key technological pursuits and future research directions of the Rima Research Institute (RRI). At present, the intelligent data analysis algorithm equipped in Lima Industrial CT can help battery manufacturers quickly and accurately analyze detection data, discover product defects, and optimize production processes. Meanwhile, image feature enhancement methods based on artificial intelligence can significantly improve image quality and adapt to high shot detection scenarios such as online stacked cell Over Han analysis. After enhancement, the operability of image analysis is greatly improved.

Automation and intelligence are the trend in the development of industrial CT testing. High performance X-ray sources and detectors, efficient reconstruction algorithms, and intelligent data analysis algorithms are key technological pursuit points and the main direction of future research at the Rima Research Institute (RRI).

At present, the intelligent data analysis algorithm equipped on Lima Industrial CT can help battery manufacturers quickly and accurately analyze detection data, discover product defects, and optimize production processes. Meanwhile, AI based image feature enhancement methods can significantly improve image quality and adapt to high beat detection scenarios such as online stacked cell Over Han analysis. After enhancement, the operability of image analysis is greatly improved.

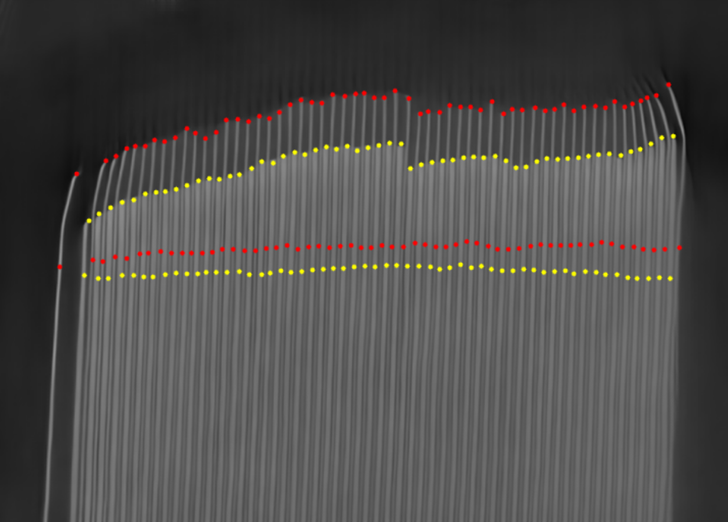

Lima automatic OH detection software uses deep learning based methods to segment the positive and negative electrode regions of the inspected image and calculate the endpoint Overhang value. It has the advantages of high efficiency and high repeatability, and the GRR result can reach 10%.

Lima automatic OH detection software uses deep learning based methods to segment the positive and negative electrode regions of the inspected image and calculate the endpoint Overhang value. It has the advantages of high efficiency and high repeatability, and the GRR result can reach 10%.

For more details on technical solutions, please visit our booth or call us.

Get in touch with us, our experts will help you