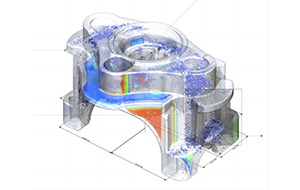

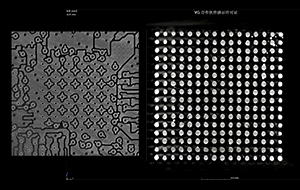

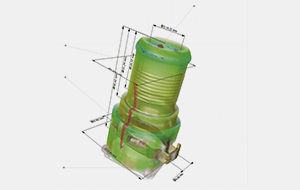

In the analysis of casting defects, it is possible to quickly and accurately reveal defects such as pores, shrinkage cavities, inclusions, cracks, etc. inside the product, analyze their causes, optimize casting processes, and improve product quality and performance.