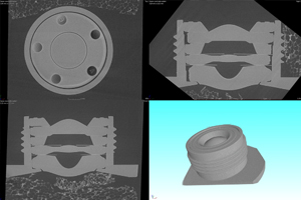

Testing scope: Internal and external products and materials, non-destructive testing for defects, testing types: pores, cracks, inclusions

Search:

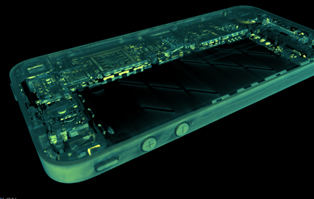

Many consumer electronics components only require simple X-ray scanning,

This can ensure the quality compliance and efficient production of its products.

Testing scope: Internal and external products and materials, non-destructive testing for defects, testing types: pores, cracks, inclusions

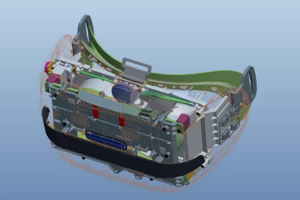

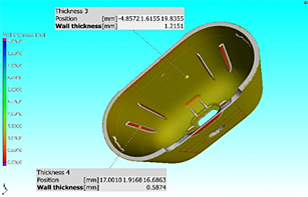

Three dimensional model fitting and measurement (some interchangeability measurements such as coaxiality, positional accuracy, roundness, line/surface profile, etc.) for measuring dimensions within and between geometric bodies to support obtaining internal structural data of unknown samples in a non-destructive state for reverse engineering manufacturing

Restore the detailed internal situation of the product, obtain complete data of the body, and analyze sample defects and failure situations accordingly

Clearly observe the assembly of electronic components in products such as mobile phones and PCB boards, and

measure the components horizontally, coaxially, and vertically

Meet the micro/nano testing requirements of electronic components and promptly identify non-conforming parts in the early stages of production