Scope of testing: Non destructive testing of internal defects in metal and non-metal products and materials Detection type: pores, cracks, inclusions

Search:

X-ray and industrial CT testing provide another "shortcut" for the foundry industry to track production issues and ensure production efficiency. This is a testing method that can bring substantial returns: it eliminates the additional costs of other testing methods, reduces the probability of product recalls, and protects the reputation of the company and its products in the minds of consumers.

Scope of testing: Non destructive testing of internal defects in metal and non-metal products and materials Detection type: pores, cracks, inclusions

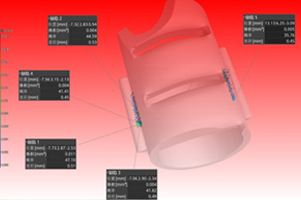

Three dimensional model fitting and measurement (some interchangeability measurements such as coaxiality, positional accuracy, roundness, line/surface profile, etc.) for measuring dimensions within and between geometric bodies to support obtaining internal structural data of unknown samples in a non-destructive state for reverse engineering manufacturing

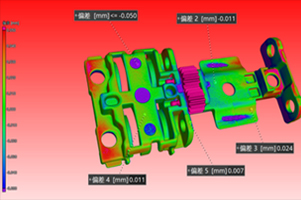

Support importing STP/CAD data and comparing it with models obtained from CT scans to determine the qualification of actual products

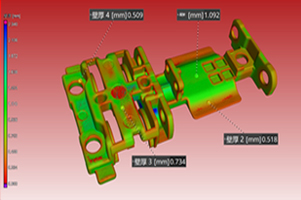

One click wall thickness analysis, obtaining wall thickness information at various positions of the sample, supporting the screening of products by pre-set qualified product wall thickness ranges. For different thickness positions, continuous or gradient color gradients can be used for identification