Hotline

Search:

Powder analysis

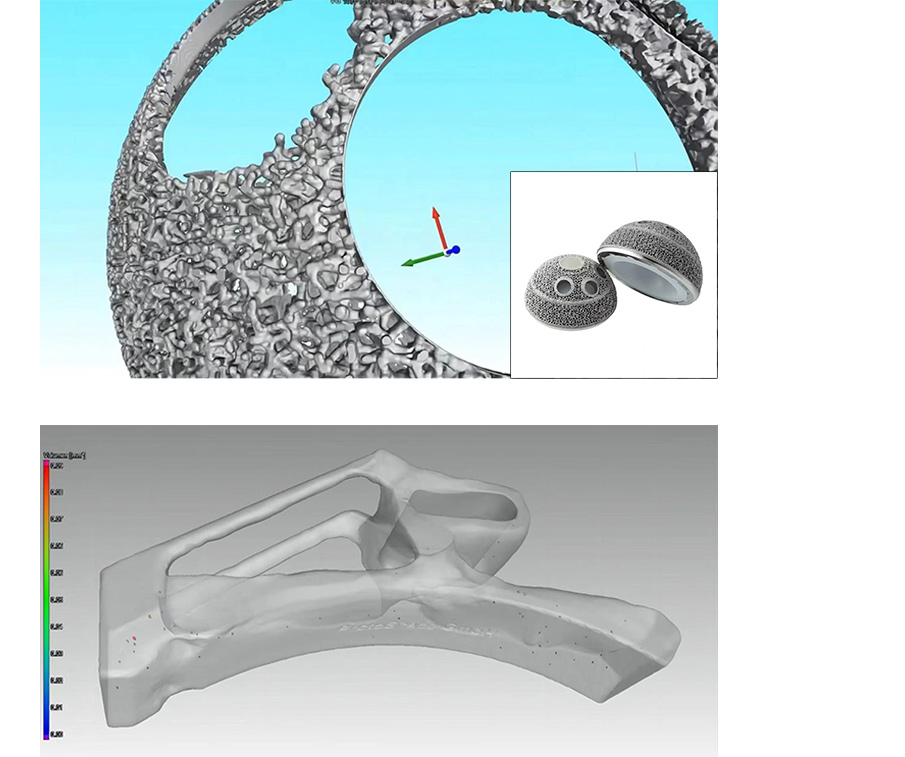

As the cornerstone of additive manufacturing components, the particle size and shape distribution of powder are crucial for the forming process. These factors not only affect the distribution and melting process of the powder, but may also cause component defects. Lima Industrial CT provides solutions for analyzing particle pollution, intercepting air, particle size and shape, ensuring precise processes.

Porosity and defect detection

The metal powder printing process often faces challenges such as porosity, porosity, and cracks. Lima Industrial CT can accurately identify pores and inclusions, and quantify their size and shape. By filtering attributes such as sphericity, compactness, and surface distance, different defect formation mechanisms can be distinguished, providing strong support for product quality control.